Racing Track Materials and Racer Safety

Ever wonder what the surface under those high‑speed wheels actually is? Most people picture just black asphalt, but the truth is a mix of materials designed for grip, durability, and safety. Knowing what goes into a track helps you understand why crashes aren’t usually about the ground itself.

Common Track Surfaces

Asphalt is the go‑to for many modern circuits. It offers a smooth, consistent feel and can be layered to handle the heat generated by racing tires. Concrete shows up on oval tracks and some street circuits because it holds up better under extreme loads and doesn’t soften in hot weather.

For off‑road events, you’ll see a blend of clay, dirt, and sometimes sand. These loose surfaces give drivers a sliding feel that’s part of the challenge. Some venues even add synthetic compounds—think rubber granules mixed into the top layer—to improve traction and reduce dust.

Where a track has multiple layouts, you might find a transition zone. That’s a thin strip where asphalt meets concrete or dirt, ensuring drivers don’t feel a sudden change that could upset the car’s balance.

How Safety Systems Protect Drivers

Even with the toughest surfaces, crashes happen. That’s why safety isn’t left to the track alone. Helmets, fire‑resistant suits, and HANS devices (Head and Neck Support) absorb the forces that hit a driver’s body.

Cars themselves act like rolling cages. Crumple zones in the chassis, roll cages, and energy‑absorbing foam keep the impact away from the driver. Modern formula cars also use carbon‑fiber monocoques that stay intact even after a high‑speed hit.

Track barriers add another layer of protection. TecPro barriers—those large, foam‑filled blocks—deform on impact, slowing a car down gently. Tire walls and SAFER (Safe Friction Energy Reduction) barriers do the same thing, turning kinetic energy into harmless heat.

All these elements work together so that the track material isn’t the main danger. Think of it like a trampoline: the surface gives you bounce, but the safety net catches you if you fall.

In practice, a driver’s risk comes more from speed, car setup, and track conditions than from the asphalt itself. Wet weather, for instance, can turn a slick asphalt surface into a sliding hazard, but drivers adjust with tires designed for rain and by lowering their speed.

If you’re curious about a specific circuit, check its official specs. Most tracks publish the exact mix of asphalt grades, concrete thickness, and any special surface treatments. Those details matter to engineers who tune cars for optimal grip.

Bottom line: racing tracks are built to be tough, consistent, and as safe as possible. The materials—whether asphalt, concrete, or a dirt‑clay blend—are chosen to give the best performance, while safety gear, car design, and barriers handle the impact when things go wrong. So the next time you watch a race, remember the science under those tires is as much about protecting drivers as it is about making the race exciting.

St Mirren Storm Into Premier Sports Cup Final With 4-1 Win Over Motherwell

St Mirren stunned Motherwell 4-1 to reach the Premier Sports Cup final, setting up a historic showdown with Celtic at Hampden Park. A rare chance for a non-Old Firm club to lift major silverware.

Read More

Curacao Makes History as Smallest Nation to Qualify for World Cup Amid Advocaat's Family Absence

Curacao became the smallest nation ever to qualify for the 2026 World Cup after a 1-1 draw with Jamaica, with coach Dick Advocaat absent due to family reasons. His record as the oldest World Cup-qualifying manager at 78 cements a historic achievement for the 160,000-population island.

Read More

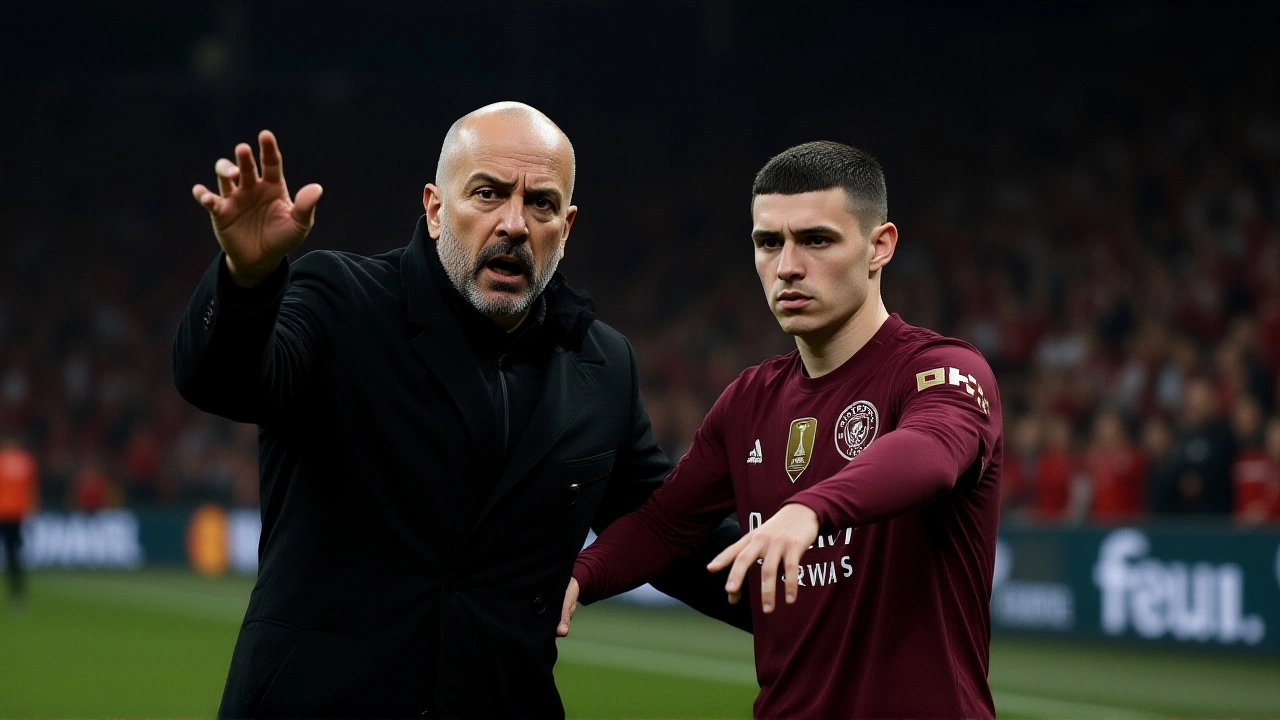

Guardiola Credits ‘Unique’ No.10 Role for Phil Foden’s Surge

Pep Guardiola says Phil Foden’s return to form stems from a central No.10 role, boosting his goals and assists while nudging England reconsideration.

Read More

Mahrez’s Rare Double‑Touch Penalty Disallowed in City‑Everton Clash

Riyad Mahrez had a rare double‑touch penalty disallowed against Everton in March 2022, sparking debate on Law 14 and its impact on Manchester City's title charge.

Read More

Neat Nepal Stuns West Indies with 19‑Run Win at Sharjah

On Sep 27 2025 Nepal edged West Indies by 19 runs at Sharjah, posting 148/8 before bowing out the Caribbean side for 129/9. A third‑wicket 50‑run stand between Rohit Paudel and Kushal Malla turned the tide after early wickets. Four West Indies debutants featured, but Nepal’s experience shone. The win gives Nepal a 1‑0 lead in the three‑match series.

Read More

What are racing tracks made from? Doesn't it hurt the racers?

Racing tracks are typically made from a blend of asphalt, concrete, and sometimes clay or dirt, depending on the type of racing. While this may sound painful, safety measures are in place to protect racers. Helmets, protective suits, and specially designed cars or bikes help absorb the impact and minimize injuries. So, while crashes can happen, the track's material isn't the main culprit. Instead, speed and racing conditions play a bigger role in the risk factor for racers.

Read More